FuelSaver

FuelSaver

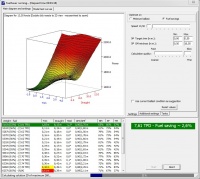

The fully integrated FuelSaver module in Easeacon is a combination of the new AutoBallast and the existing OptiTrim modules.

Based on genetic algorithms, FuelSaver saves fuel by finding a series of ballast solutions which are both checked for strength and stability, and optimized with regards to the fuel consumption at a specified speed by adjusting the draught and trim.

Not only will you be given solutions within your selected trim range, but FuelSaver can also indicate if you may save even more fuel by changing your selected criteria.

- All ballast solutions are checked for strength and stability

- Set your own criteria of minimum GM, trim, etc.

- Check savings and print reports to support fleet performance initiatives

- Fuel savings of up to 2% are easily obtained, - in the initial phase, save even more

- Supports ISO 14001 compliance

- Improve your ship’s charter value

For more information, please give us a call or send an e-mail.

Save fuel

“Probably the easiest way to save fuel during transit is to trim a vessel to its optimum draught and trim. From either model tests or CFD calculations, fuel reductions ranging from 2 – 7% have been found, depending on ship type and speed. However, for every type of vessel the ideal trim is different."

Patrick Hooijmans, MARIN.

Data for Fuelsaver

The FuelSaver module is designed to be based on either model tests or CFD.

If a suitable mathematical 3D-model is already available, e.g. from the design stage, this technology is especially suitable to calculate the correlations between speed, draught, trim and power need. Generally, a set of test data should comprise of approx. 120 points of correlated values of trim, draught, speed and power in order to establish an adequate basis for the FuelSaver optimizations.

If not, model tests or CFD calculations can be made. We can assist with the contact to the companies which perform model test/CFD calculations.

Model tests

Model test results - typically obtained from towed and self-propelled model testing in water. Such tests are often made on the design stage for a series of sister ships.Often these tests are concentrated around the design point for the ship, i.e. to prove that the specified speed at the design draught can be obtained with the expected engine power. In such cases it is important to advise the yard or designers that more combinations are required in order for the Easeacon FuelSaver to calculate better trim and ballasting alternatives.

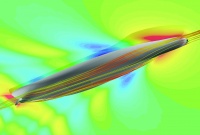

CFD

Computational Fluid Dynamics (CFD) - an alternative to model tests in water - are based on Reynolds Average Navier-Stokes (RANS). RANS-CFD is the fastest developing area in marine fluid dynamics. Based on fundamental laws (first principle) of mass and momentum conservation, CFD methods provide versatile and increasingly fast solutions.